Efficient Powder Handling with IBCs: Cleaner, Smarter, and More Reliable

What Are IBCs in Powder Handling?

Intermediate Bulk Containers (IBCs) are versatile, reusable containers used for storing, transporting, and processing dry powders and granular materials in industries like pharmaceuticals, food & beverage, chemicals, and nutraceuticals.

When integrated with discharge systems — such as cone valves — IBCs become a powerful tool for improving powder flow, containment, hygiene, and operational flexibility.

Key Benefits of Powder Handling with IBCs

🛢️ Dust-Free Operation

IBCs enable closed powder transfer, dramatically reducing airborne dust and improving worker safety. This is especially critical in industries handling toxic, potent, or allergenic powders.

🧪 No Product

Cross-Contamination

Each IBC is dedicated to a specific batch or recipe. This eliminates the risk of cross-contamination, which is vital in regulated environments like pharmaceuticals and food production.

🛡️ Segregation-Free Transfer

Powder blends can segregate when transferred via pneumatic conveyors or gravity chutes. Coen Valve IBCs maintain blend uniformity from the mixer to the point of use, ensuring product quality and consistency.

⏱️ Faster Recipe Changeovers

IBCs operate in a batch-based, decoupled manufacturing system. This allows for quick changeovers between recipes with minimal cleaning, reducing downtime and improving throughput.

🚿 Reduced Cleaning & Downtime

Since the product remains inside the IBC, there's less contact with transfer lines or equipment, which means less cleaning between batches — saving time, water, and cleaning agents.

⚙️ Mass Flow Discharge (with Cone Valve IBCs)

Cone Valve IBCs promote mass flow discharge, preventing common flow issues like bridging, rat-holing, or inconsistent dosing. They handle even cohesive or poor-flowing powders with ease.

🏭 Modular & Scalable Systems

IBC systems are modular by nature. You can scale operations by adding more IBCs, discharge stations, or automation without overhauling the entire process — ideal for growing manufacturers.

📦 Parallel Processing & Zero Downtime

With IBC systems, blending, storage, and discharge run in parallel, so one IBC operates while another is prepared—eliminating cleaning delays and ensuring continuous, high-throughput production.

🏷️ Improved Material Traceability

Each IBC can be barcoded or RFID-tagged for full traceability, supporting batch control, inventory tracking, and compliance with regulations like GMP or FDA.

📃 Flexible Multi-Recipe Production

IBCs support parallel processing — multiple recipes can run at the same time using separate IBCs. This is ideal for contract manufacturers or facilities with high product variety.

🥼 Hygienic, GMP-Compliant Design

Stainless steel IBCs and associated handling equipment are designed for easy cleaning, sanitary operation, and regulatory compliance, making them ideal for cleanroom environments.

🧤 Reliable Powder Handling

Cone Valve IBC systems ensure consistent, clean, safe powder flow—whether working with free-flowing granules or sticky, cohesive powders.

Who Should Use IBC Systems for Powder Handling?

IBC powder handling solutions are ideal for manufacturers that need:

- Batch integrity and traceability

- Reduced cleaning and setup times

- Safe handling of toxic or dusty powders

- Greater flexibility in production scheduling

- Compliance with GMP, ATEX, or FDA standards

Industries benefiting from IBC systems include:

- Pharmaceuticals

- Food & Beverage

- Chemicals

- Nutraceuticals

- Cosmetics & Personal Care

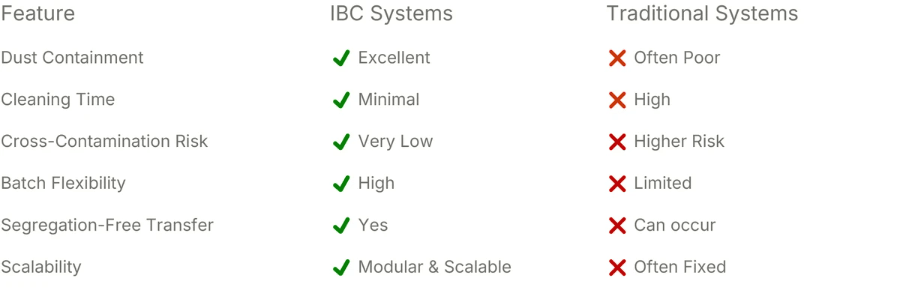

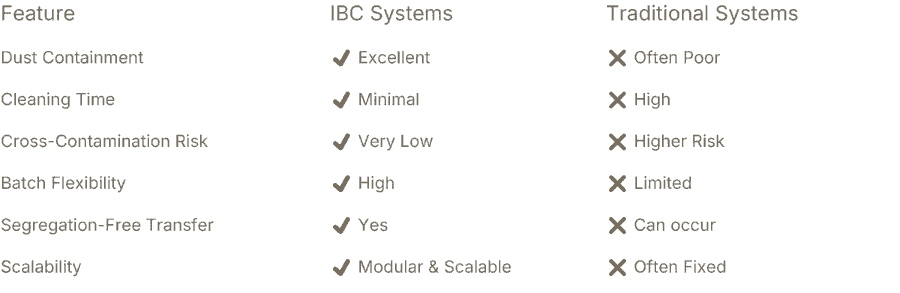

IBC Powder Handling vs Traditional Systems

Get Expert Advice on IBC Powder Handling Systems

Looking to implement or upgrade your IBC system? We help manufacturers across South East Asia design and install fully compliant powder handling solutions with Cone Valve IBC technology. Contact us today for a consultation or equipment demo.

CONEBOX PTE. LTD. (202326932E)

160 Robinson Road, #14-04 Singapore Business Federation Center, Singapore 068914

Tel (SG): + 65 8678 3109 (Whatsapp)

Tel (MY): + 6010 246 2478

Website: www.conebox.co

Email: info@conebox.co

Copyright © 2023-Present.

Conebox Pte. Ltd. All Rights Reserved