Cone Valve IBCs vs Butterfly Valve IBCs:

Which Is Better for Powder Handling?

Why Valve Matters in Powder IBC Systems:

Intermediate Bulk Containers (IBCs) are central to modern powder handling systems — but the valve design at the bottom of the container can make or break your process.

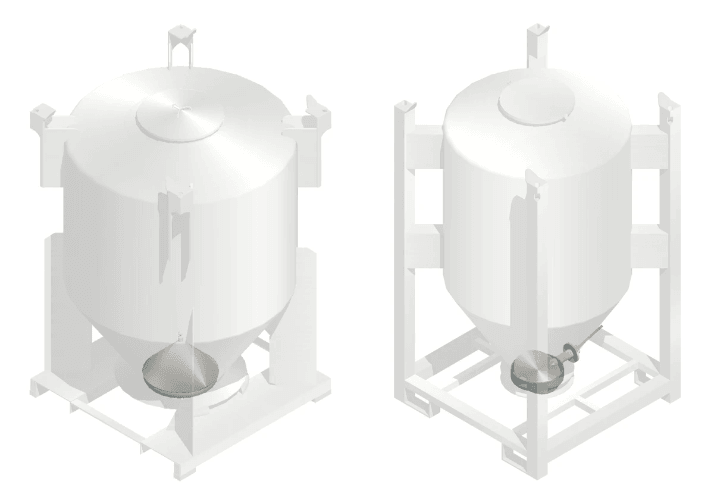

Two common IBC types are Cone Valve IBCs and Butterfly Valve IBCs. Both look similar externally, but they perform very differently when it comes to flow control, product integrity, dust containment, and operational efficiency.

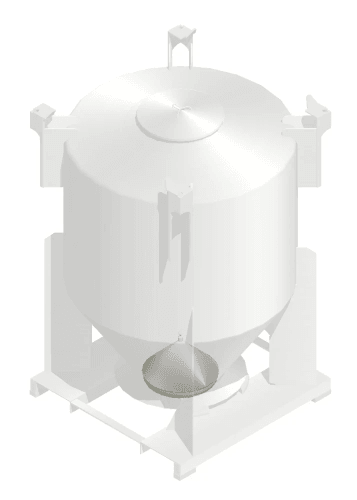

What Is a Cone Valve IBC?

The Cone Valve IBC features a patented, conical discharge valve integrated into the base of the container. The cone lifts vertically to:

- Promote mass flow of powders

- Break up bridging and rat-holing during discharge

- Control the flow rate from start to finish

- Deliver segregation-free discharge

The cone movement agitates the powder above it, ensuring a consistent and controlled flow —especially for cohesive, sticky, or poorly flowing powders.

What Is a Butterfly Valve IBC?

The Butterfly Valve IBC uses a simple rotating disc to open or close the outlet. It is a low-cost solution, often used for free-flowing materials. However, this valve:

- Does not promote mass flow

- Cannot effectively control discharge rate

- Often causes rat-holing or blockage

- Can result in powder segregation and uncontrolled discharge

Butterfly valves are also more prone to leakage, dust emission, and manual handling risks during operation.

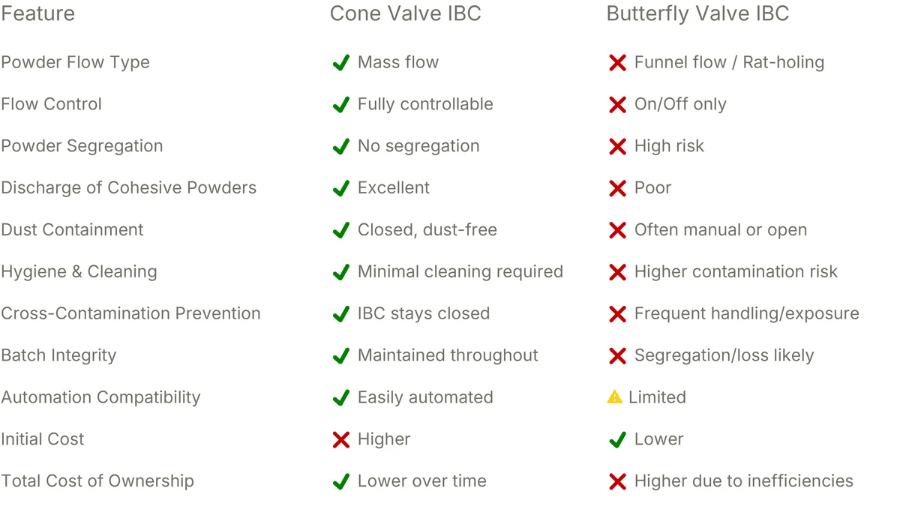

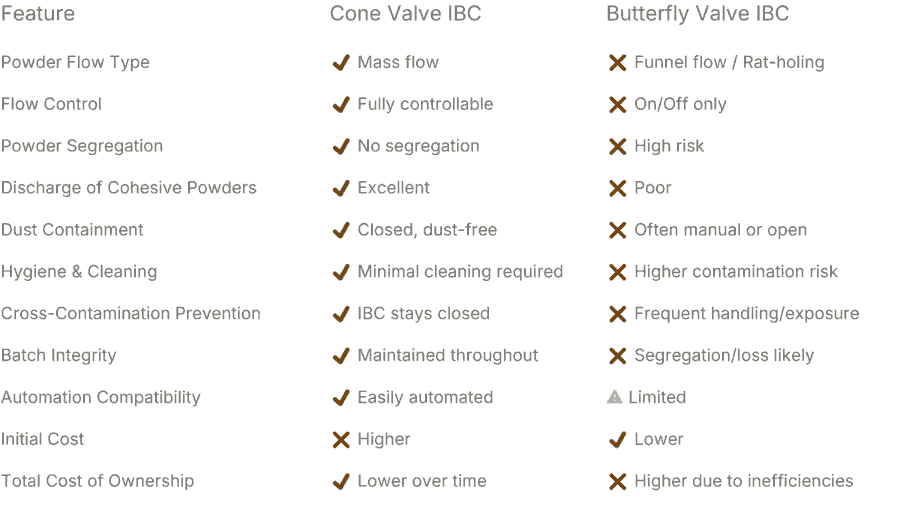

Side-by-Side Comparison: Cone Valve vs Butterfly Valve IBCs

Key Benefits of Cone Valve IBCs

⚙️ Mass Flow Discharge (with Cone Valve IBCs)

The cone lifts to create mass flow — eliminating bridging, clumping, or rat-holing, even with sticky powders like milk proteins, titanium dioxide, or pharmaceutical blends.

🛡️ No Product Segregation

Butterfly valves often cause powders to separate during flow. Cone Valve IBCs maintain homogeneous blends from filling to discharge — preserving product quality.

🎚️ Precise Flow Control

With automated actuation, Cone Valve IBCs offer variable flow rates, enabling accurate batch dosing, partial discharge, and loss-in-weight feeding.

🛢️ Dust-Free Operation

A sealed discharge interface means no product exposure, protecting operators and ensuring cleanroom compliance in GMP environments.

🚿 Less Cleaning, More Uptime

Unlike butterfly valve IBCs, Cone Valve systems don’t need cleaning between recipes, as the product remains fully contained in its own vessel.

🧤 Safe Handling of Hazardous Powders

Ideal for high-potency APIs, toxic chemicals, or allergenic food powders, where containment and hygiene are critical.

When to Upgrade from Butterfly to Cone Valve IBCs

You should consider switching to Cone Valve IBCs if you:

- Handle difficult, cohesive, or fine powders

- Require batch integrity and segregation-free transfer

- Need fast recipe changeovers and low cleaning time

- Operate under GMP, ATEX, or FDA regulations

- Want to future-proof your plant with scalable, automated handling systems

Trusted in Southeast Asia & Beyond

Manufacturers across Malaysia, Singapore, the Philippines, Indonesia, Vietnam, Thailand, and the broader ASEAN region are already upgrading to Cone Valve IBC systems to meet growing demands for:

- Flexibility

- Hygiene

- Automation

- Consistency

From pharmaceutical APIs to food pre-mixes and cosmetic powders, Cone Valve IBCs deliver consistent results with minimal risk.

Ready to Make the Switch?

Our team helps manufacturers transition from outdated butterfly valve systems to fully integrated Cone Valve IBC solutions — with local support across Southeast Asia. Let’s improve your powder handling performance. Contact us now for a system assessment or on-site demo.

CONEBOX PTE. LTD. (202326932E)

160 Robinson Road, #14-04 Singapore Business Federation Center, Singapore 068914

Tel (SG): + 65 8678 3109 (Whatsapp)

Tel (MY): + 6010 246 2478

Website: www.conebox.co

Email: info@conebox.co

Copyright © 2023-Present.

Conebox Pte. Ltd. All Rights Reserved