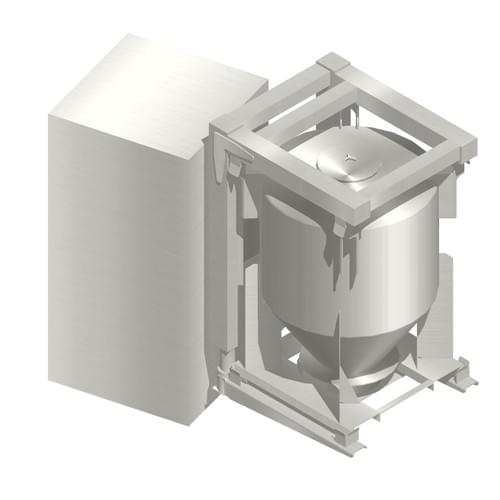

Cone Valve IBC Blending System

• Smart, Scalable Powder Mixing – No Cleaning Required

The Cone Valve IBC Blending System is a game-changer for manufacturers needing fast, flexible, and hygienic powder blending. By rotating the IBC itself, product is mixed inside the container it’s already stored in, eliminating the need for transfer into fixed mixers — and eliminating cleaning downtime altogether.

Whether you produce 20 or 200+ recipes, this system is built to handle frequent changeovers, diverse batch sizes, and multiple IBC capacities — all while ensuring product integrity and operator safety.

🔷 Key Benefits

- Zero Cleaning Downtime – instant recipe changeovers without cross-contamination

- Recipe & Batch Flexibility – handle a wide range of ingredients and IBC sizes

- Preserve Product Quality – gentle or high-shear mixing options

- Operator Safety Built-In – fully enclosed, hands-free operation

- GMP-Compliant Design – meets hygiene and validation standards

- Future-Proof Technology – scalable for growing product portfolios

✨ Key Features

⏱️ No Cleaning Downtime with Instant Recipe Changeover

Because mixing occurs inside the sealed IBC, there's no product contact with the blender hardware. This eliminates the need to clean equipment between recipes — enabling:

- Instant recipe switches

- Increased throughput

- Zero risk of cross-contamination

- Full batch traceability

- Mix one batch. Swap the IBC. Start the next recipe immediately.

⚙️ Optional High Shear Mixing Module

For products that require intensified mixing, our system offers a high-shear intensifier option. This enhances blend uniformity for:

- Minor ingredients

- Flavour dispersion

- Agglomerated powders

You get the flexibility to mix both sensitive and demanding formulations in the same system.

Switch between gentle or aggressive mixing depending on the product.

📦 Mix IBC Sizes from 200L to 3500L

The IBC blending system accepts a wide range of IBC sizes with adjustable clamp systems and automated positioning. Whether you're handling small R&D batches or full-scale production runs, the same blender can support your needs.

- 200L | 500L | 1000L | 1500L | 2000L | 3500L

- No need for multiple mixers — one platform does it all

- Achieve batch flexibility without duplicating equipment.

🧪 Gentle, Uniform Mixing

The system provides 3D tumbling motion with full rotational control, delivering:

- Even distribution of active ingredients

- Minimal particle degradation

- Low energy consumption

It’s ideal for mixing fragile powders such as:

- Pharmaceutical blends

- Food flavours and spices

- Nutraceutical ingredients

- Cosmetic powders

Maintain the integrity of delicate or friable materials.

🛡️ Safe Operations for Operators

Safety is engineered into every detail:

- Fully enclosed system

- No manual handling of open powder containers

- Interlocked access points and auto-stop functions

- Operator interfaces for safe, automated control

Minimise operator exposure and workplace risks.

🔧 Future-Proof Technology

Designed for modular expansion, our Cone Valve IBC Blending System can grow with your needs:

- Add barcode scanning for recipe tracking

- Integrate with MES or ERP systems

- Automate loading/unloading and docking

- Compatible with Cone Valve IBC Filling, Discharge & Washing systems

Upgrade without replacing your core system.

🏭 Applications

Ideal for manufacturers that require frequent batch changes, low contamination risk, and high product variability:

- Pharmaceuticals – APIs, excipients, direct compression blends

- Food & Beverage – spices, protein, premixes, milk powders

- Nutraceuticals – herbal blends, probiotics

- Chemicals – additives, pigments

- Cosmetics – mineral powders, colourants

🌍 Designed for Southeast Asia’s Leading Manufacturers

With installations across the Philippines, Malaysia, Singapore, Thailand, Vietnam, and Indonesia, we support regional compliance and provide local servicing, training, and validation support.

✉️ Talk to Our Powder Blending Experts

Ready to eliminate cleaning downtime and streamline your blending operations?

We’ll help you design a Cone Valve IBC Blending System tailored to your batch sizes, product types, and growth goals.

- Request a Consultation

- Book a Live Demo

- Integrate with Other Mixing Technology