Advanced Powder Handling with Integrated Mixing Solutions

In today’s high-performance manufacturing environments, powder handling and dry mixing must be hygienic, flexible, and efficient. Intermediate Bulk Containers (IBCs) offer a modular, scalable platform that combines mixing, storage, and transfer in one closed, contamination-free system.

With the right mixing technology — from IBC blending systems to ribbon mixers and paddle mixers — manufacturers can achieve uniform blends, fast changeovers, and compliance with GMP and food-grade standards.

IBC Blenders (In-Container Mixing)

The IBC itself is rotated or tumbled using a bin blender or IBC blender.

Powders are mixed within the same container used for transfer.

Eliminates the need for product transfer between mixer and storage.

No cleaning between batches — simply swap the IBC.

Perfect for sensitive recipes, small batches, or multi-product facilities.

Ribbon Mixers

- Ideal for homogenizing dry powders with similar particle sizes and densities.

- A rotating ribbon agitator moves powder axially and radially.

- Can be paired with Cone Valve IBCs for controlled discharge into the mixer or from the mixer into the IBC.

Best for mixing applications which require medium intensity.

Why Combine IBCs with Mixing Equipment?

By integrating dry mixing with IBC-based handling, you unlock a range of operational advantages:

🚿 Reduced Cleaning Time

- Eliminate the need to clean fixed mixers between batches when using IBC blenders.

- For traditional mixers, IBCs allow cleaning to beperformed offline by swapping with clean IBCs to resume production

⚙️ Faster Changeovers

- Each batch or recipe stays in its dedicated IBC.

- Swap IBCs — not the equipment — between recipes.

🛡️ No Cross-Contamination

- Closed-system design keeps each batch isolated.

- Critical in facilities handling allergens, APIs, or flavour variants.

🌟 Improved Batch Integrity

- Avoid segregation by minimizing powder movement.

- Maintain uniformity from blend to discharge to packing.

🛢️ Flexible Production

- Run multiple recipes in parallel using multiple IBCs or mixer connections.

- Scale capacity by adding IBCs, not building new lines.

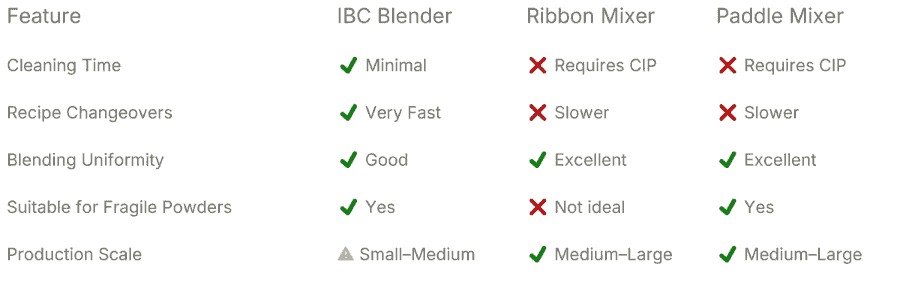

When to Use IBC Blenders vs Ribbon or Paddle Mixers

Applications Across Industries

Dry powder mixing with IBCs is ideal for:

- Pharmaceuticals – APIs, excipients, direct compression blends

- Food & Beverage – premixes, spices, milk powders, protein

- Nutraceuticals – herbal blends, probiotics, vitamin formulations

- Chemicals – pigments, additives, detergents

- Cosmetics – talc, powders, colorants

Integrate with Cone Valve Technology for Total Flow Control

Cone Valve IBCs offer controlled, mass flow discharge, ideal for discharged mixed powders without bridging or inconsistent flow. Pairing cone valve technology with dry mixers allows for:

- Improved efficiency with no waiting time for filling and emptying mixers

- Clean, dust-free discharge into or from mixers

- Smooth flow even with cohesive or poor-flowing powders

Future-Proof Your Powder Handling

By combining IBC handling with advanced mixing technologies, your plant gains:

- Maximum flexibility for new product launches

- Batch traceability and quality assurance

- Reduced labour and cleaning costs

- Lower downtime and higher output

CONEBOX PTE. LTD. (202326932E)

160 Robinson Road, #14-04 Singapore Business Federation Center, Singapore 068914

Tel (SG): + 65 8678 3109 (Whatsapp)

Tel (MY): + 6010 246 2478

Website: www.conebox.co

Email: info@conebox.co

Copyright © 2023-Present.

Conebox Pte. Ltd. All Rights Reserved