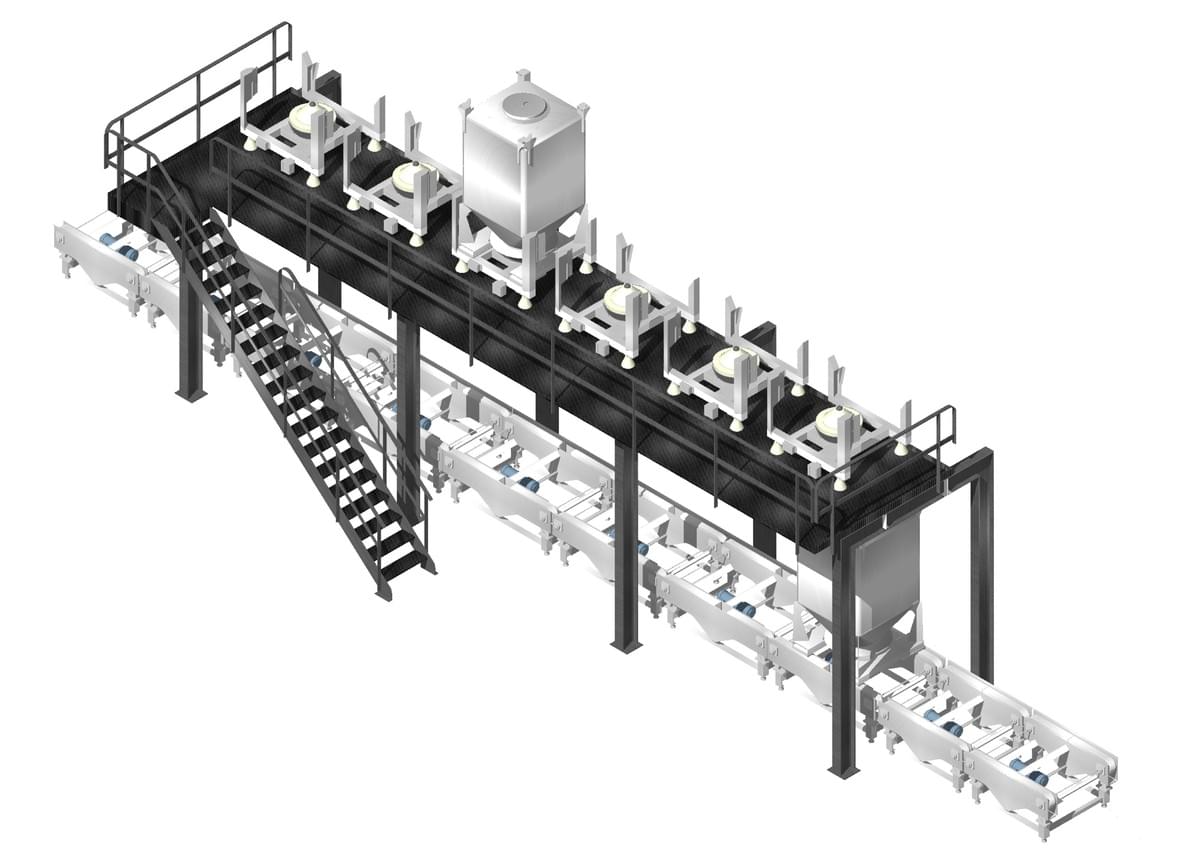

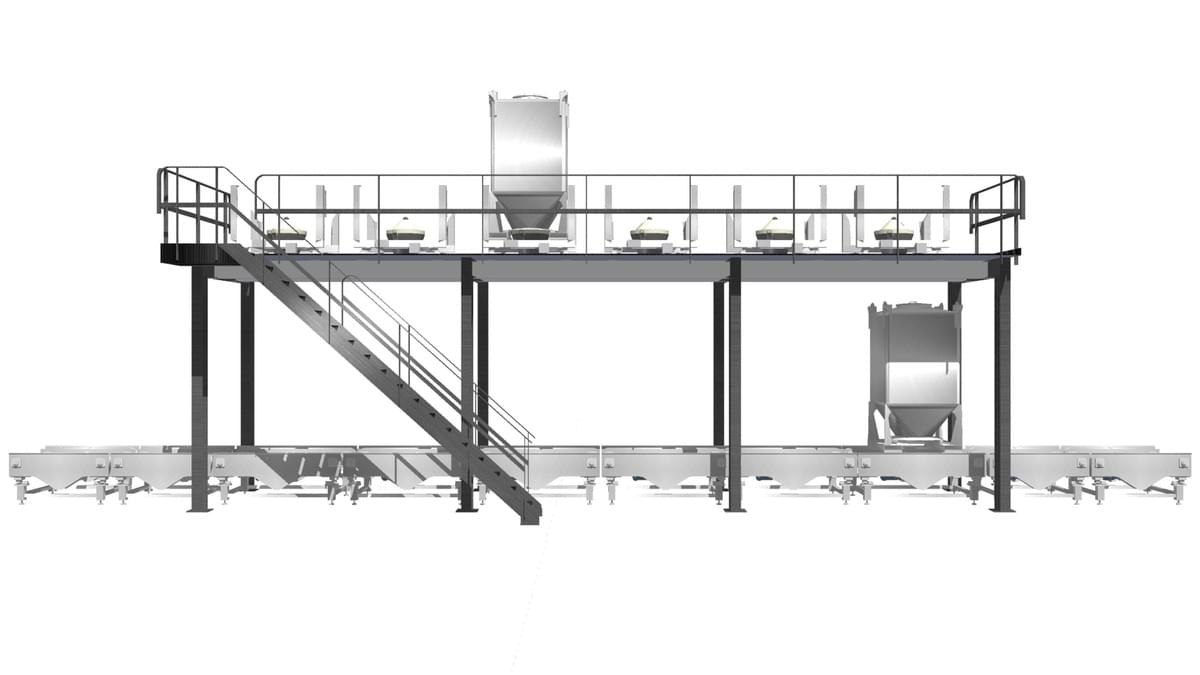

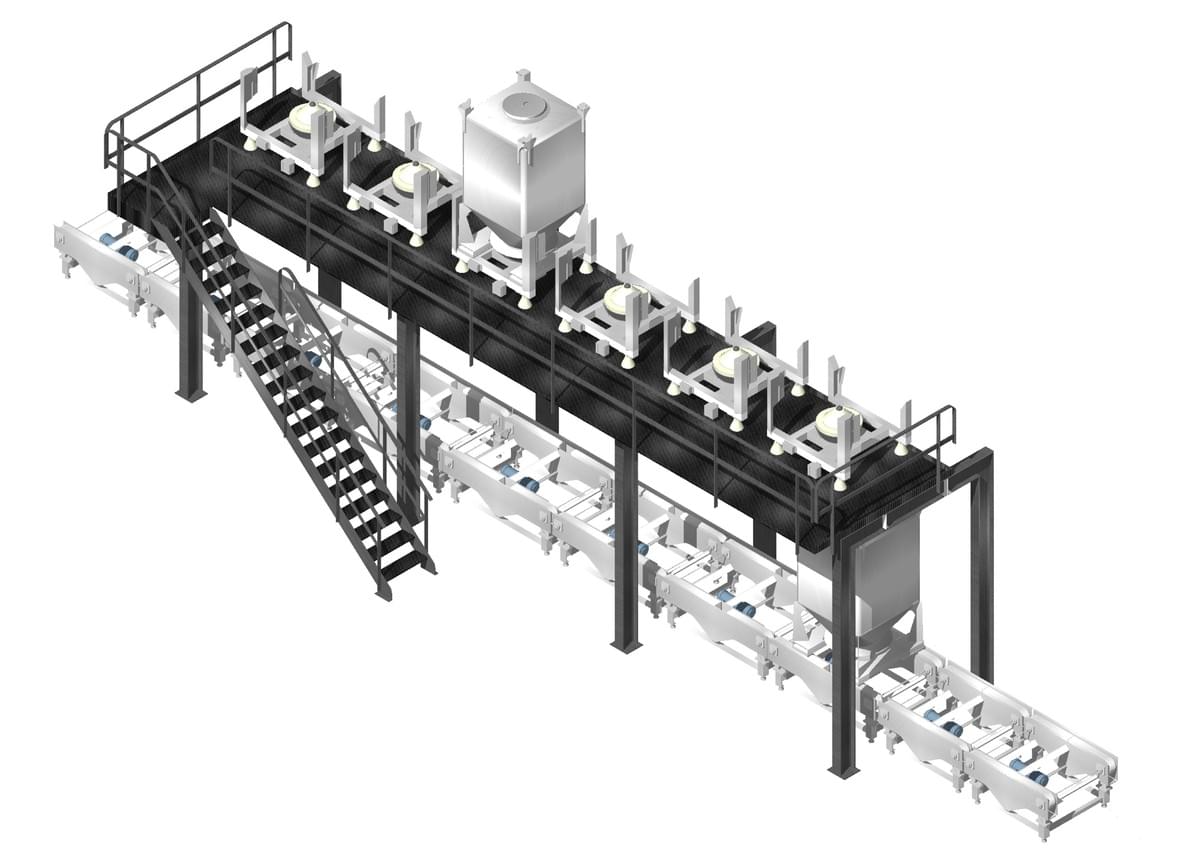

Automated Formulation Ingredients Handling System

with Cone Valve IBCs

Accurate | Clean | Scalable | Future-Ready

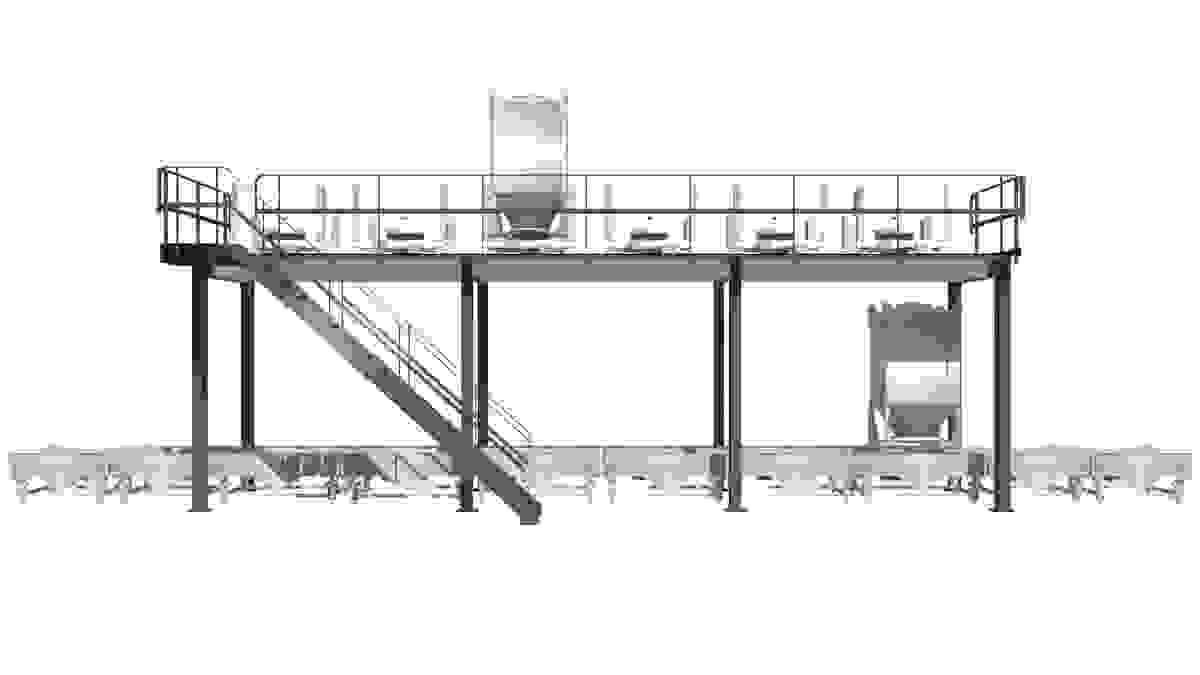

Looking for a solution that ensures precise dosing, reliable weighing, and automated batching of multiple ingredients—without the risk of cross-contamination? Our Automated Formulation Ingredient Handling System, built around Cone Valve IBCs (Intermediate Bulk Containers), is the smart choice for modern manufacturers demanding batch accuracy, traceability, and long-term flexibility.

Designed for Precise Dosing, Weighing & Batching

At the core of the system is our automated multi-ingredient batching platform, capable of handling a wide range of powders, granules, and bulk solids. Integrated with Cone Valve IBCs, it delivers:

- High-accuracy dosing with controlled, repeatable ingredient flow

- Precise weighing with integrated load cells and recipe-based automation

- Consistent batching across multiple ingredients, ensuring product uniformity

Whether you're batching five or fifty ingredients, the system ensures that every formulation is executed with consistency and control.

Key Features and Benefits

⚙️ Zero Cross-Contamination

Cone Valve IBCs provide sealed,dust-free transfer, eliminating contamination risks between batches or ingredients. Ideal for allergen-sensitive applications, pharmaceutical environments, and regulated industries.

🛡️ Flexible Ingredient Handling

The system accommodates a wide range of material types—from free-flowing powders to sticky or cohesive blends. Cone Valve technology prevents segregation and ensures a consistent flow, even with difficult-to-handle ingredients.

🌟 Complete Batch Traceability

Every batch is automatically recorded, including:

Ingredient source and weightOperator actions and time stamps

recipe version and batch number

Easily integrate with MES,ERP, or SCADA systems to support GMP, FDA, or ISO compliance.

🛢️ Scalable and Future-Proof

Whether you're expanding your production line or preparing for new product development, this system is designed to scale:

Add more IBC stationsIntroduce new ingredients

Increase output volume without redesign

It’s built to adapt to unknownfuture ingredients and changing production needs, making it a true long-term investment.

How the System Works

1🧪IBCs Loaded

with Ingredients

Each Cone Valve IBC contains a specific ingredient in a sealed vessel.

2⚖️Automated Transfer & Weighing

Ingredients are discharged under control into batching IBCs sitting on load cells.

3🌀Batching & Mixing

Based on pre-set recipes, ingredients are precisely batched and transferred to the next stage.

4🏷️Data Logging

& Traceability

Every step is digitally tracked and recorded for compliance and quality assurance.

Ideal for Multiple Industries

Our automated system supports manufacturers in:

Pharmaceuticals

GMP-compliant ingredient control

Food & Beverage

Allergen separation and hygiene-focused transfer

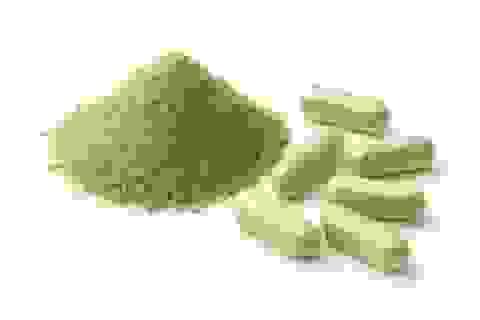

Nutraceuticals

Flexibility for changing formulations

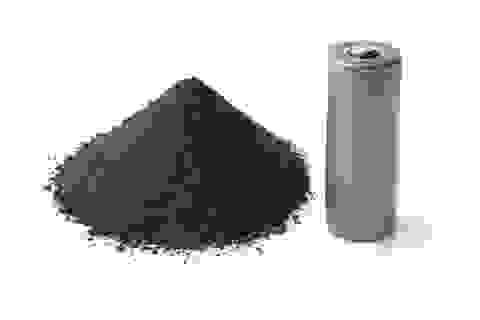

Chemical Processing

Safe, sealed powder handling

Cosmetics & Personal Care

Precision in active ingredient batching

Built for Southeast Asian Manufacturers

Whether you’re operating in Singapore, Malaysia, Thailand, Indonesia, Vietnam, or the Philippines, this system supports:

- Local support and installation available across SEA

- Compact, modular designs suitable for various factory layouts

- Humidity-resistant components ideal for tropical climates

- Compliance with local and global regulations (GMP, HACCP, Halal, or ASEAN food regulations)

Designed for Today. Ready for Tomorrow.

Whether you're building a new facility, modernizing an aging process, or planning to scale up production, our Automated Formulation System with Cone Valve IBCs offers the flexibility and performance you need—without compromise.

Contact us today to discover how you can streamline your formulation process while maintaining batch integrity, traceability, and future adaptability.

CONEBOX PTE. LTD. (202326932E)

160 Robinson Road, #14-04 Singapore Business Federation Center, Singapore 068914

Tel (SG): + 65 8678 3109 (Whatsapp)

Tel (MY): + 6010 246 2478

Website: www.conebox.co

Email: info@conebox.co

Copyright © 2023-Present.

Conebox Pte. Ltd. All Rights Reserved