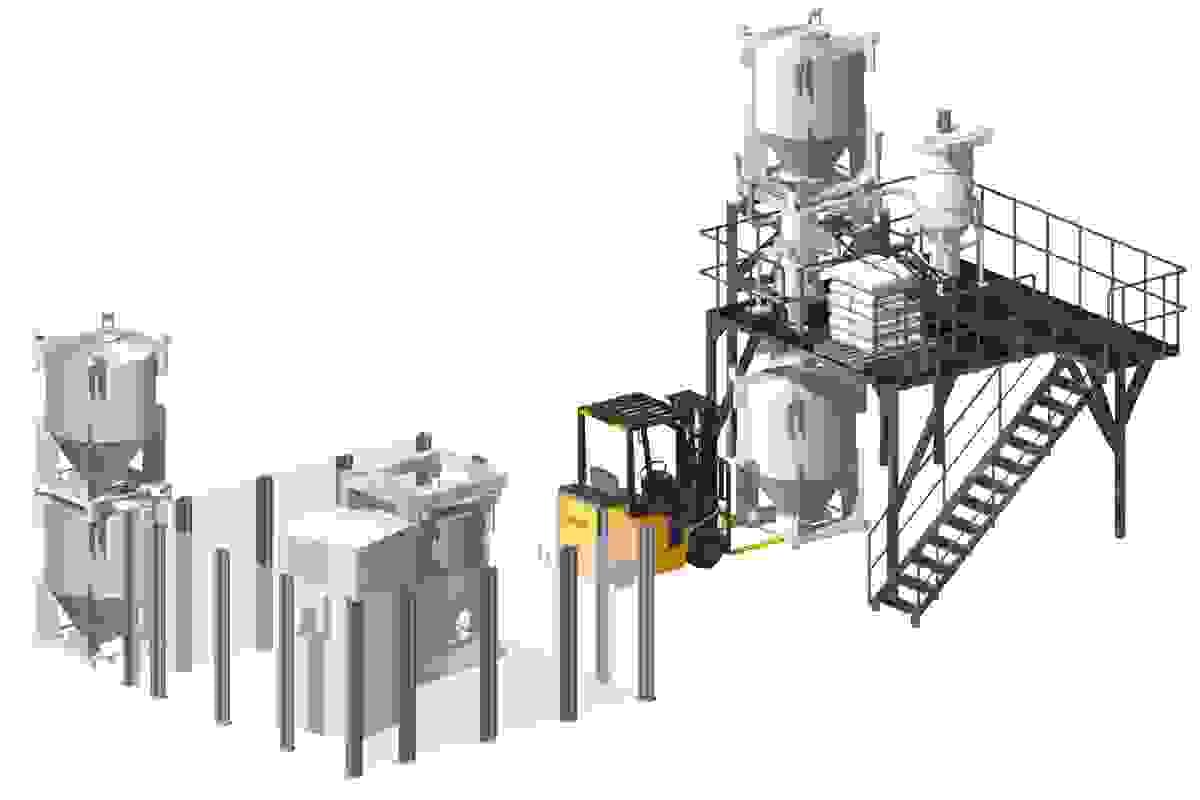

Future-Proof Cone Valve IBC Systems for High-Performance Powder Processing

Hygienic, modular, and efficient powder handling solutions for manufacturers across South East Asia — enabling fast recipe changeovers, dust-free operations, and segregation-free powder handling.

At Conebox, We Provide

Cutting-edge Cone Valve IBC (Intermediate Bulk Container) systems that redefine how powders are handled, mixed, and transferred in high-value production environments.

Our systems are trusted by manufacturers across South East Asia who require hygienic, flexible, and efficient powder handling — especially in multi-recipe, batch-based operations.

Designed for industries like pharmaceuticals, food & beverage, nutraceuticals, and chemicals, our solutions deliver safe, precise, and scalable powder processing with minimal cleaning time, no cross-contamination, and maximum productivity.

Unlock the Key Advantages of Cone Valve IBC Technology

Our Cone Valve IBCs offer significant performance advantages over traditional butterfly valve or slide gate systems:

⚙️ Mass Flow Discharge

Prevent bridging, rat-holing, and inconsistent discharge — even with challenging or cohesive powders.

🛡️ No Segregation

Maintain blend integrity during transfer. Perfect for preserving uniformity in dry-mix and multi-ingredient formulations.

🛢️ Dust-Free, Hygienic Operation

Closed systems reduce dust emissions and product loss while meeting strict GMP and food-grade hygiene standards.

⏱️ Quick Recipe Changeovers

Batch-based IBC handling eliminates fixed lines, allowing for fast product switches without cross-contamination risk.

🚿 Reduced Cleaning Downtime

No need to clean downstream equipment between recipes — saving hours per changeover and increasing daily throughput.

🎚️ Controlled Powder Flow

Integrated Cone Valve technology allows precise flow control and accurate dosing — crucial for consistent batch processing.

📃 Multiple Recipes, Simultaneously

Use multiple IBCs in parallel to manage diverse products in the same facility — with complete batch traceability.

🏭 Modular & Scalable System

Start small and scale fast. Add more IBCs, filling/discharge stations, or automation features as your production grows.

🏷️ Future-Proof Solution

Our systems are designed for long-term use, supporting automation, traceability, and integration with Industry 4.0 platforms.

Whether you're handling free-flowing granules or sticky, cohesive powders, Cone Valve IBC systems deliver consistent, clean, and safe powder flow — every time.

Our Solutions

Explore our fully integrated powder handling systems based on Cone Valve IBCs:

- IBC Discharge Stations with Flow Control

- IBC Filling Stations

- Dosing & Weighing Integration

- IBC Blending with or without High Shear

- Cleaning Systems (WIP/CIP)

- Full range of IBCs (200L-3500L)

- Turnkey IBC Handling Systems

Need a single unit or a full turnkey system? We support your operations from concept to commissioning.

Designed for South East Asia’s Leading Industries

We proudly serve a growing customer base across ASEAN countries — offering full support in:

- Pharmaceuticals – API blending, granules, direct compression blends

- Food & Beverage – protein powders, milk derivatives, seasonings

- Nutraceuticals – vitamins, herbal powders, probiotics

- Chemical & Cosmetic Industries – pigments, resins, talc, base powders

Why Choose Conebox?

- Over 15 Years of Regional Experience

- Local Support in Southeast Asia

- Custom Solutions for Complex Powders

- Compliant with GMP, ATEX & FDA Standards

- Global Technology with ASEAN Expertise

Our Client Success Story

“Thanks to the Cone Valve IBC system, we now run three recipes side by side with zero cross-contamination and cut changeover time by 75%. It’s a game-changer for our multi-product facility.”

— Executive Director, Instant Beverages Manufacturer, Malaysia

Get in Touch

Speak with our IBC specialists today. Let’s build your next-generation powder handling system.

Ready to Upgrade?

Transform your powder handling with a hygienic, modular, and future-ready IBC system.

CONEBOX PTE. LTD. (202326932E)

160 Robinson Road, #14-04 Singapore Business Federation Center, Singapore 068914

Tel (SG): + 65 8678 3109 (Whatsapp)

Tel (MY): + 6010 246 2478

Website: www.conebox.co

Email: info@conebox.co

Copyright © 2023-Present.

Conebox Pte. Ltd. All Rights Reserved